Spend less than 10 minutes reading all about the insight into Creality CR-10. We gathered the various opinions inlcuding famous video bloggers and manufacturing services on Treatstock to provide our readers with must-read information, including reviews, tips and hacks.

- What 3D printing community leaders are saying about CR 10

- What manufacturing services on Treatstock are saying about CR 10

- Recommendations for CR 10 buyers

- Results of the survey for CR 10 owners

- Final Verdict from Treatstock

- F.A.Q. about Creality CR-10

- CR-10S vs CR-10

- Creality CR-10 vs Ender 3

Main specifications of CR-10

| Min. Layer Thickness: | 0.1 mm (in some cases 0.05 mm) |

| Printing Precision: | ±0.1 mm |

| Nozzle Diameters: | 0.2 mm, 0.3 mm, 0.4 mm |

| Printing Speed: | ≤200 mm/s |

| Compatible filaments: | PLA, TPU, Wood, Copper, Rubber |

| Standard Print Size: | 300 x 300 x 400 mm |

Application:

- Biological medical clinical guidelines

- Customise, internet date printing service

- Sand table, structure model printing

- Toys, Cartoon, culture creative industry

- Prototyping, Review, function verification

- Overseas market

- Education, DIY Maker

Background of the Creality CR-10

The CR 10 is manufactured in China by a company called Shenzhen Creality 3D Technology Co., Ltd., which was founded five years ago in 2014. They have wasted no time in becoming one of the most successful manufacturers of 3D printers in China, having obtained a number of international quality certifications, independent intellectual property rights and dozens of patents. Apart from several series of FDM (Fused Deposition Modeling) machines, they also produce a DLP (Digital Light Processing) 3D printer for jewelry and dental called the Creality 3D DP001, and a range of filaments.

The Creality CR-10 was released in July 2016 and is the fourth-generation printer in the Creality series. The CR-7 was the first model that came out back in 2014, followed by the Creality CR-8 a year later. The CR-9 stands out from the earlier models with its closed high precision 3D printer DIY kit and relatively small print size 150 x 150 x 100 mm. The CR 10 was proceeded by the CR-10S with certain upgrades, but even in 2019, the “original” CR 10 seems to be the best value for money.

What the 3D printing community is saying about the CR-10

Nearly all the reviews from bloggers are full of excitement and delight. Slight issues occur very seldom, but even then, they seem to be easily resolved. Here are some of the reviews.

“I just love how really impressive printers like this are becoming more user-friendly and more affordable this thing is awesome and I have no hesitation right now recommending it to all of you if it's within your price range.”

2. RCLifeOn

“I found with the printer that heated bed takes a long time to heat up and was only able to reach 85 degrees celsius this causes ABS to cool down too quickly resulting in the layer separation you can see right here the solution is really quite simple you need to enclose the printer trap the heat inside and once again I was blown away by the perfectly layered layers ... I was happily surprised by how great this printer works. In conclusion, this is my preferred 3D printer right now. I highly recommend it to anyone looking for a good performance printer!”

“If you take into consideration the quality at which it can print, the materials at which it can print, the price you can get it for and how easy it is to operate, it's quite easy to conclude that at the moment that I'm filming this, this is the best printer that you can get for your money”.

What manufacturing services on Treatstock are saying about the CR-10

We sent a questionnaire out to our top manufacturers that use Creality CR-10 printers and have provided their detailed feedback here.

1. For which applications do you use your Creality CR-10?

Most of the services that have experience in using the CR-10 consider it to be an almost universal multi-functional machine. For instance, AllThingss3D, a print service from Belgium, uses it “…for anything really, big or small: statues, functional parts, etc.”. The prominent build size allows the manufacturing of huge prints with good quality says Al from 3DPros, a print service in Texas. He goes on to say: “Due to the larger print bed I typically use it to make larger parts that require less detail. I have a smaller Wanhao i3 that I use for more detailed prints. The CR-10 is perfectly suited to details as well with the standard 0.4 nozzle”.

2. Which materials have you found to produce the best results with the Creality CR-10?

Most CR-10 owners primarily use PLA filament, as well as ABS, PET and PETG. “So far, I have had great results with PET and PLA. This printer can definitely compete with other semi-professional printers on the market. It's reliable for long and large prints. The smooth surface of printed object are just perfect”, says Pierre Fabrié, the owner of iFab3D located in France. 3DPros states: “I have had the best luck with hatchbox ABS, the brand makes more of a difference in ABS than in PLA in my experience”. It seems that even exotic materials like nylon or flexible filament can be used after some small upgrades says AllThingss3D.

3. How would you rate the reliability of the Creality CR-10?

Most manufacturers rate the reliability of CR-10 highly. “Very reliable. I have been printing a lot with it since I got it (at least one print per day), and have gotten great results out of the box with no calibration other than adjusting flow rate”, says 3DPros. They go on to say that overall, it’s: “…an amazing printer for the price; nothing even comes close price wise that has a similar build volume”. However, it seems that not all CR-10 models are produced equal and sometimes the quality leaves much to be desired. Nicholas Winter operates Humanisticnick’s Printing Service in Pennsylvania and wrote that the CR-10 is more reliable than some of his cheap kits but not compared to his other machines. “Bed was difficult to get level, lots of zits on the prints, single Z axis created issues with some Z-Banding”, he says.

4. Have you had any issues with the Creality CR-10 and if so, what were they?

Owners of CR-10 shared the common problems they’ve had and in some cases offered solutions for them as well. Although you might not necessarily experience the same problems, as they say, forewarned is forearmed.

5. If you could change anything about the Creality CR-10, what would it be?

One Creality is good, THREE is better!

It turned out that amongst the manufacturers on Treatstock is Andrew Davie - one of the moderators for the biggest Creality CR-10 group on Facebook (almost 30k subscribers). He is the man behind Doctor Boo's Astounding 3D Printing Press in Tasmania. He willingly answered our questions and shared his thoughts about the CR-10, giving some useful recommendations for other owners as well.

3 x Creality CR-10

I actually have three CR-10 machines. Two of those belong to work, but I’m a full-time operator of them and I was responsible for purchase. The first was about 6 months ago, and the latest about 2 months ago.

Usage

For personal usage I get my Creality 3D printer to help me create repair parts and upgrades for the CR-10 and other printers. For work, I design and print enclosures for sensors to detect bees coming and going from beehives. I’m also building some robotics stuff.

Reliability

I have found all three units to be extremely reliable. I was fortunate, because warped bed-glass is common on these machines. I did not have this problem. However, it’s not a push-button machine - you have to know what you’re doing and understand what symptoms you’re seeing in prints and how to correct them. But once you have experience, the machine is a joy to use.

Main PROs

It’s cheap - under $400 - and produces superb prints. I would have no hesitation buying one again. It was the perfect choice for my first printer. I now also own two Ender-2 machines, which are essentially the same, but with a smaller print area and slightly better-quality prints. Also highly recommended.

Main CONs

The wiring is a bit all over the place, and the control box is ugly. Perhaps the very worst thing is that the fans are quite noisy. The good thing is that just about everything is easy for the average-skill tinkerer to replace/fix. The various upgrades such as belt tensioners and adjustment wheels that you can print should probably be included rather than having to print them yourself. But to be honest, making a good machine into a great machine is half the fun. It’s a great machine, with superb quality for the price.

Results of the questionnaire for Creality CR-10 owners

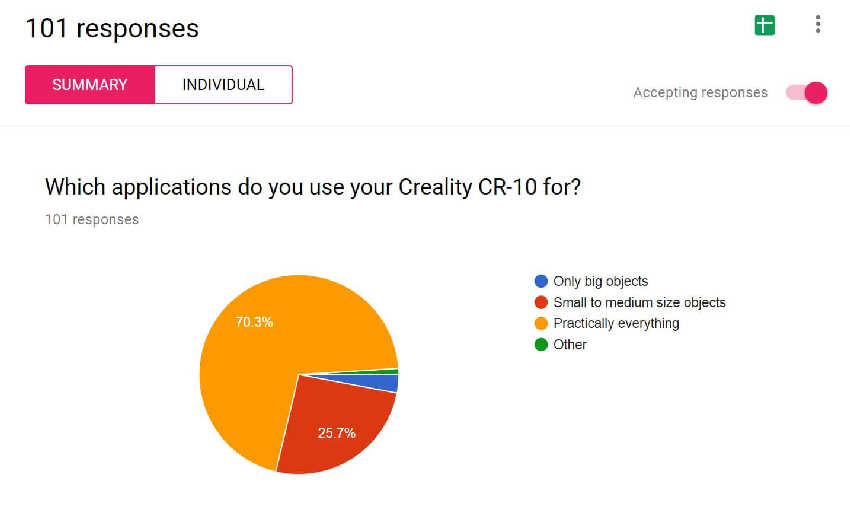

1. Which applications do you use your Creality CR-10 for?

Most of CR-10 owners state that they use it for almost everything. It comes as no surprise really, as it combines both a large build volume with high-quality.

2. Which materials have you found to produce the best results?

95% of respondents answered that they prefer PLA, leaving the other materials in its wake. Coming in at second place was PET/PETG, with 22 respondents claiming this is another material they use.

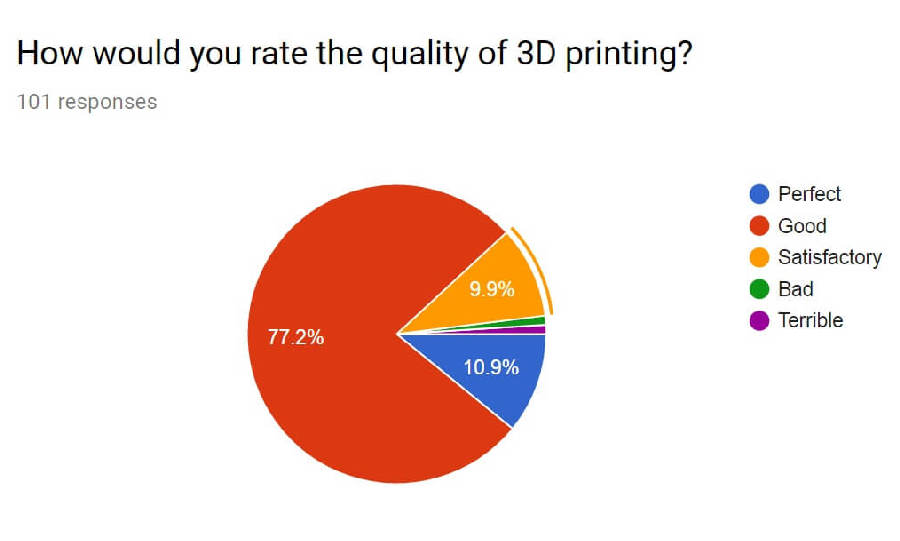

3. How would you rate the quality of 3D printing?

77% of respondents consider the quality of 3D printing to be good, 10% found it perfect and another 10% were satisfied with it. Very few found the quality of 3D printing to be terrible/bad.

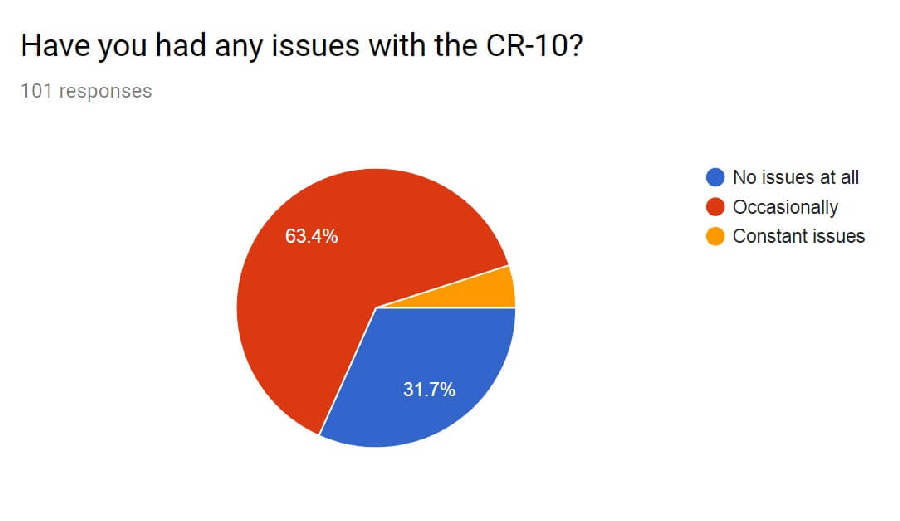

4. Have you had any issues with the CR-10?

Most owners claim to occasionally have issues with the CR-10 and about 5% have issues all the time. However, 33% of respondents said they’ve had no issues at all!

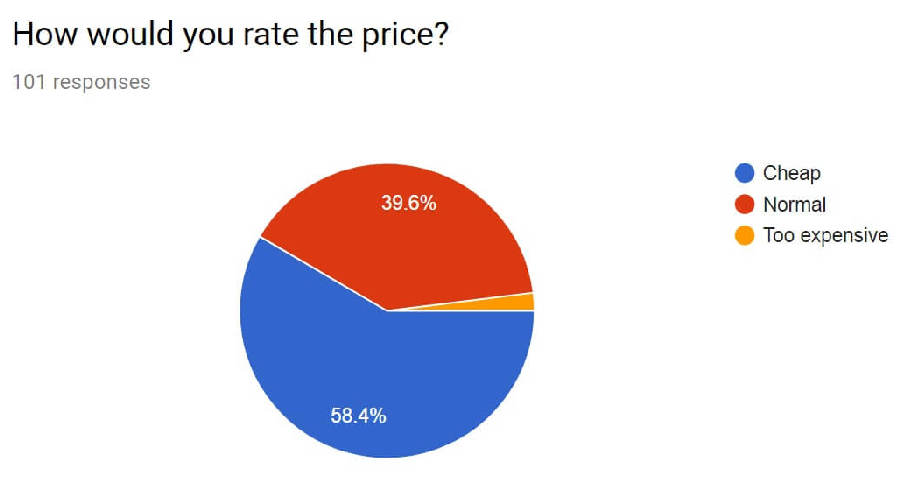

5. How would you rate the price?

More than 50% of CR-10 users consider the price to be good value considering its capabilities.

Do you agree with the results of the questionnaire? If you have another opinion, share it in the comments below! You can also answer the following questionnaire.

Verdict from Treatstock

As far as we see, the Creality CR-10 regarding its price is an outstanding machine. Yes, it’s not perfect (well none of them are really), but the quality and build volume sets it apart from its competitors. Both famous bloggers and Treatstock manufacturers (most of them) agree on that and recommend the CR-10 to both entry-level and experienced manufacturers. Owners must be prepared to roll up their sleeves as it’s not a plug-and-play machine and from time to time there can be some issues. However, there is a large community of almost 30,000 enthusiasts on Facebook that are always ready to help owners solve their problems: "Creality CR-10 3d Printer User Group".If you are not sure about whether to buy it or not, you can order a test print from one of our services. You can also ask questions, we will be glad to reply to them.

F.A.Q. about Creality CR-10

How to properly set up the Creality CR-10?

Most owners claim that it’s very easy to put the Creality CR-10 together. However, you should keep in mind that this machine still demands a certain amount of skill and knowledge. Some screws can be lost during shipping, so it’s better to check that they’ve all arrived before starting, and don’t forget to adjust the wheels on each axis. If you can spin the wheel and not move the axis, it needs a little adjustment. It’s also important to check the flatness of the glass and if it’s warped, you can either purchase a replacement glass or a mirror from IKEA."It’s not a push-button machine - you have to know what you’re doing and understand what symptoms you’re seeing in prints and how to correct them. But once you have experience, the machine is a joy to use", says Andrew Davie. He is the man behind the manufacturing service Doctor Boo's Astounding 3D Printing Press on Treatstock and moderator for the biggest Creality CR-10 group on Facebook.

Is the Creality CR-10 compatible with Slic3r ?

Creality CR-10 works well with slicing softwares such as Cura, Simplify3D and Slic3r.

Can you put a dual extruder on a Creality CR-10?

It’s possible in theory, and you can even find instructions and a dual extruder design on thingiverse.com However, it’s quite hard to do it without a high level of technical skills and knowledge.

Does the Creality CR-10 have a heated bed?

Yes, Creality CR-10 has a heated print bed.

What size of filament does the Creality CR-10 use?

1.75 mm

- What is the difference between the CR-10 and CR-10S?

The major differences are that the Creality CR-10S has Bootloader, an Extra Z Motor and filament sensor, whereas the CR-10 doesn’t. But in general, there's no difference in print quality between the two models. If you need a detailed comparison, here is a video review by Nexi Tech:

- Is the Creality CR-10 the same as the Hictop CR-10?

They look the same, and some of you may be wondering whether it’s just a re-branding or another version of the CR-10? Well, a Hictop representative claims that the “original” Creality CR-10 and the version sold by Hictop are the exact same products and that Hictop is just an authorized seller.

- Creality Ender 3 vs CR 10

RCLifeOn made a review of the Ender 3. He used it for 3D printing flexible filament, PLA plastic, nylon and ceramic material. According to his video in some ways Ender 3 is actually better than Creality CR-10. If you don't need a large building volume and want to save some money, Ender 3 is probably the more preferable option. Give your opinion taking part in the survey.

向朋友分享 :