Copper is a soft non-magnetic metal notable for its thermal and electrical conductivity. It is used for electrical parts as well as building material. Commonly copper isn’t used in pure form but rather utilized in a range of alloys for improved machinability and properties.

订购 Copper

Copper is easily identifiable by its pinkish-orange color. This material had been in use for thousands of years due to appearing in a malleable metallic form in nature. Nowadays, copper is commonly combined with other metals such as zinc, nickel, aluminum, and others to form a more tough alloy. Though, copper-based alloys do still contain a high percentage of copper with additional metal components not reaching over 40%. These machinable copper alloy families include:

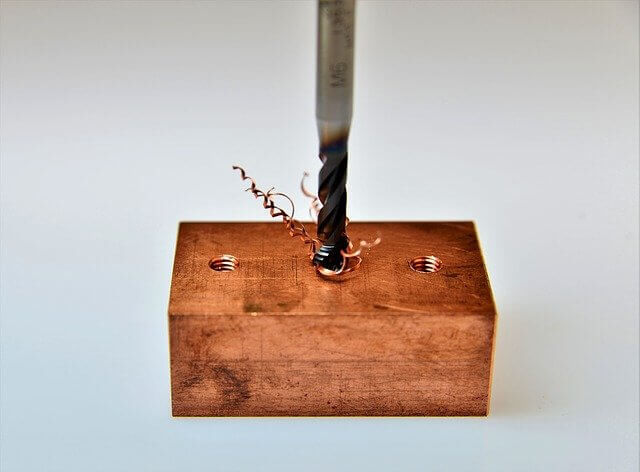

Pure copper appears very malleable and soft making it extremely tough to machine it to precise tolerances. Therefore, copper alloys are used for machined parts.

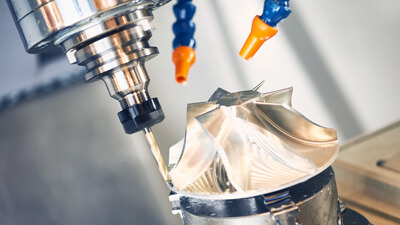

Brass, bronze, as well as numerous other copper-based alloys, on the other hand, are relatively easy to mill and cut. They also require lower cutting forces compared to metals like steel or titanium. One of the most popular choices for contract turning and machining is free-cutting brass (CuZn39Pb3), which has one of the highest machining ratings, determining how easy material is to work with.

Alternative ways to manufacture machined copper parts include coining, forging, photoengraving, or acid etching and stamping or forming.

Copper (as well as many of its alloys) is a reflective material, which complicates the laser cutting process. Improved fiber laser cutters, though, are able to process copper alloys without leaving defects on the surface.

Alloys with a great copper percentage in composition (over 96%) are used more in casting or forming technologies for parts requiring high electrical and thermal conductivity. Casted copper provides good tensile strength as well, making it suitable for bearings and gears and used in the transportation sector.

Mild steel exhibits better hardness and stiffness than pure copper, which is soft and malleable.

Surface treatments like coating and electroplating can help reduce the oxidation of copper parts.

所有的评论 (0)